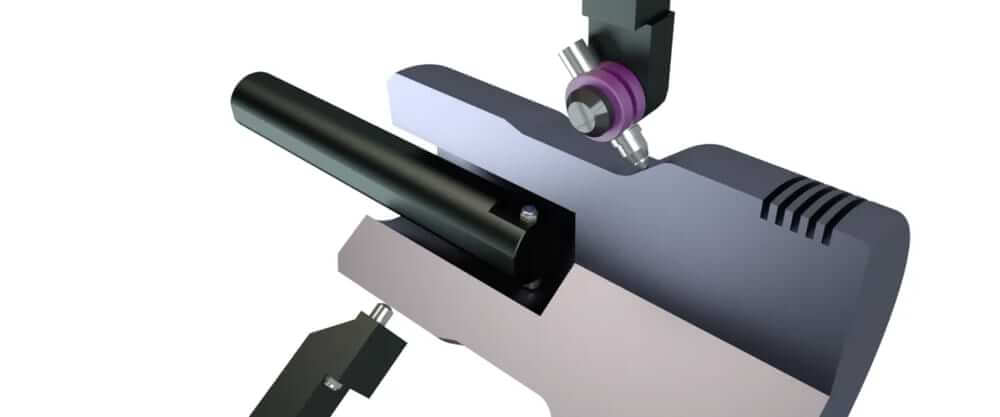

Diamond Burnishing Tools

Diamond Burnishing is a finishing process that resembles turning kinematically but without chip removal, in which a deforming tool with a spherical grounded and polished diaomnd slides under pressure over the surface of the workpiece, causing plastic deformation.

The main merits of the process are improving the corrosion and wear resistance, increasing the microhardness, decreasing the surface roughness, inducing compressive residual stresses, and refining the microstructure of the surface.

As a result of that, the fatigue strength of the workpiece will be improved. These advantages make it possible to substitute grinding by using diamond burnishing of hard-turned steel components.

Both conventional and CNC lathe machines are mostly used for performing the burnishing process. As the workpiece rotates, the burnishing head is forced against it and moves axially. The basic controlling parameters of the diamond burnisging process are the

burnishing force (, N),

burnishing feed (, mm/rev),

rotational speed of the component (, rpm),

or the burnishing speed (, m/min),

and the wear of the diamond radius (, mm).

So far, many studies have been conducted to investigate the influence of burnishing parameters and their interactions on the outputs of the diamond burnishing process, like surface roughness, surface residual stresses, microhardness, and microstructure.

The results of those studies show that the efficacy of the diamond burnishing process highly depends on the range of the applied burnishing parameters and their interactions, the type of burnished material and its hardness, and the environment of the burnishing process, like lubrication and wear of the diamond radius.

Diamond Burnishing Tools made in Sweden since 1965. DSAB